Field service operations are no longer just about fixing what’s broken. In today’s competitive and fast-paced service landscape, companies must equip their technicians with the tools and insights to address both problems with reactive and proactive solutions. The goal isn’t to replace one with the other but to strike the right balance between the two.

This blog explores how service-based organizations can strengthen their field operations by empowering technicians to switch seamlessly between urgent, on-the-spot repairs and strategic, data-driven maintenance.

Understanding Reactive and Proactive Field Service

Before diving into the tools and strategies, it’s essential to understand what each approach means and how they contribute to a well-rounded field service model.

Reactive Field Service: Fast and Flexible

Reactive field service refers to the traditional model of responding to service needs after an issue has occurred. This includes:

- Emergency repairs

- Responding to customer complaints

- Handling equipment failures

- Performing unplanned service visits

Despite being unplanned, reactive work is essential. It allows organizations to remain flexible and responsive, providing immediate support when things go wrong. In industries where downtime is costly, this approach can help maintain trust and minimize business disruption.

However, reactive service often leads to:

- Higher operational costs

- Increased technician burnout due to unexpected scheduling

- Lower first-time fix rates if technicians lack access to full-service history or diagnostics

Proactive Field Service: Predict and Prevent

Proactive field service focuses on prevention. Rather than waiting for something to break, technicians are deployed based on data, performance insights, and asset history.

Key characteristics of proactive service include:

- Predictive maintenance based on IoT sensor data

- Regular inspections and condition-based maintenance

- Scheduling service based on usage trends and risk levels

- Keeping assets operating at peak efficiency

Proactive strategies improve:

- Asset lifespan

- First-time fix rates

- Technician planning and efficiency

- Customer satisfaction through fewer disruptions

Why Technicians Need to Be Equipped for Both

Most organizations deal with a mix of scheduled service and unexpected calls. That’s why the field technician’s toolkit must support both scenarios:

- When something breaks, technicians need access to customer history, real-time communication, and the ability to diagnose quickly.

- For planned work, they should have predictive data, asset condition reports, and optimized schedules that minimize idle time.

Modern field service platforms make this hybrid approach possible, giving teams the flexibility to be responsive and preventative.

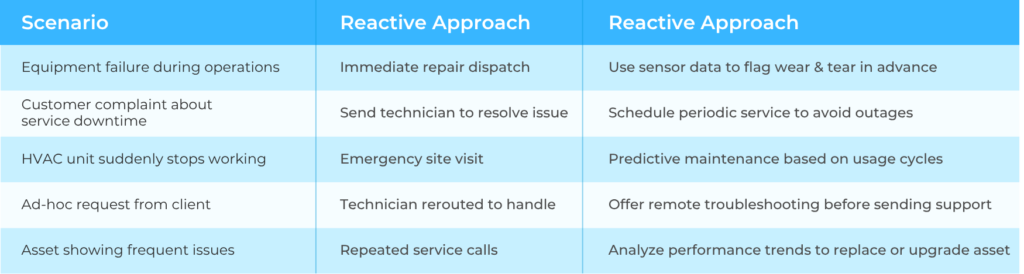

Common Use Cases for Reactive and Proactive Service

Here’s how both methods play a role in day-to-day operations:

Digital Tools That Support a Hybrid Approach

The modern technician’s toolkit now includes much more than a wrench and a clipboard. The right digital tools can turn them into problem-solvers and data interpreters who can act both reactively and proactively.

1. Mobile Field Service Apps

Mobile apps allow technicians to:

- Access job schedules and client history on the go

- Capture service notes and photos

- Complete digital checklists

- Submit service reports in real time

This is crucial when responding to emergency calls and when preparing for planned maintenance tasks.

2. Predictive Analytics & IoT

IoT sensors and predictive maintenance software analyze:

- Temperature fluctuations

- Vibration patterns

- Energy usage trends

These insights allow dispatchers and technicians to plan service before failures happen, reducing downtime and minimizing major repairs.

3. Smart Scheduling

AI-powered scheduling tools optimize:

- Technician routes

- Time windows for planned visits

- Priority based on service level agreements (SLAs) and asset condition

These tools help ensure emergency requests are addressed without completely disrupting proactive work.

Real-Time Visibility: Supporting Field Teams on the Move

Technicians often operate independently, far from supervisors or central offices. That’s why field managers need real-time dashboards and communication tools that:

- Show technician locations and job progress

- Allow instant schedule updates

- Track parts usage and inventory

- Collect service feedback for quality improvement

With these capabilities, field teams become more responsive without sacrificing structure and planning.

Technician Training for a Smarter Workforce

The role of a modern technician goes beyond hands-on work. Organizations should invest in training that covers:

- Digital tool usage (mobile apps, diagnostics, sensors)

- Communication skills for both urgent and routine service calls

- Data interpretation for predictive maintenance

- Time management and planning

The more informed and skilled the technician, the more effective both reactive and proactive strategies become.

Combining Strengths: A Unified Service Model

Organizations don’t need to choose between reactive and proactive methods. Instead, the best-performing teams:

- Use data to plan ahead

- Respond quickly when needed

- Equip technicians with mobile, intelligent tools

- Optimize technician time with smart scheduling

- Continuously train and support their field staff

This hybrid model reduces cost, improves uptime, and boosts customer trust all while enhancing technician satisfaction.

Conclusion: Stay Ahead, Respond Better

The future of field service isn’t purely predictive or reactive; it’s both. By giving technicians the tools to anticipate problems and respond swiftly to the unexpected, companies can build stronger service models.

Empowering technicians with the right technology, training, and support leads to better decision-making in the field, higher first-time fix rates, and a service operation that delivers results under pressure and over time.

With the right mix of proactive planning and responsive agility, field service teams can truly stay ahead of the job.